기술데이터

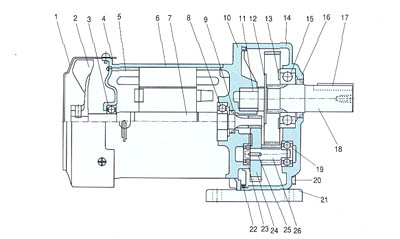

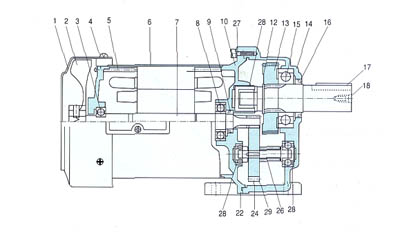

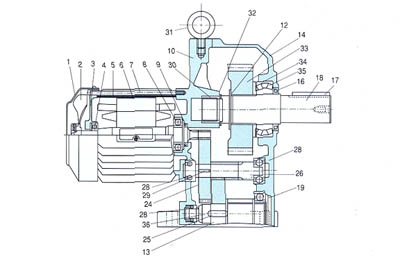

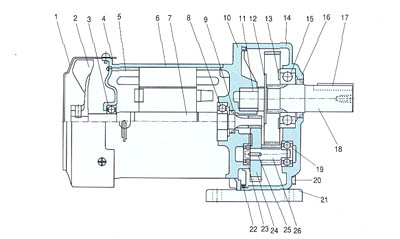

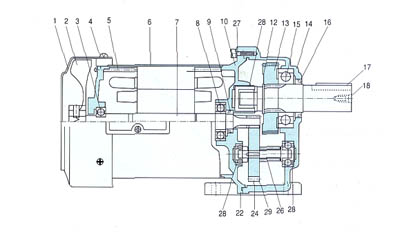

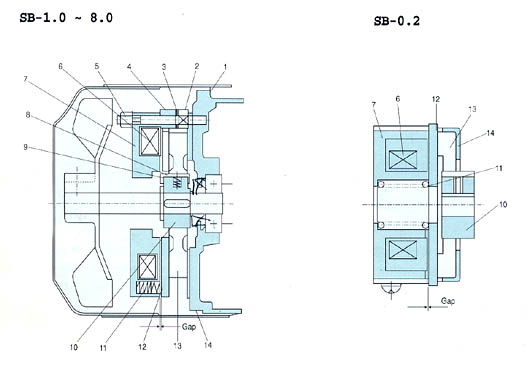

내부구조도

1. Fan Cover

2. Fan

3, Bearing

4. Bracket Shield

5. Motor Bolt

6. Motor Frame

7. Motor Shaft

8. Bearing

9. Oil Seal

10. Motor Flange

11. DX Bush

12. Snap Ring

13. Gear B

14. Case

15. Bearing

16. Oil Seal

17. Key

18. Output Shaft

19. Bearing

20. Drain Plug

21. Hex Bolt

22. O-Ring

23. Bearing

24. Gear A

25. Key

26. Pinion B

27. Wrench Bolt

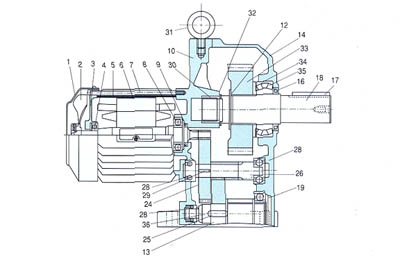

28. DX Bearing

29. Key

30. Needle Bearing

31. Eye Bolt

32. Thrust Collar

33. Gear C

34. Thrust C

35. Roller Bearing

36 Pinion C

|

|

|

|

|

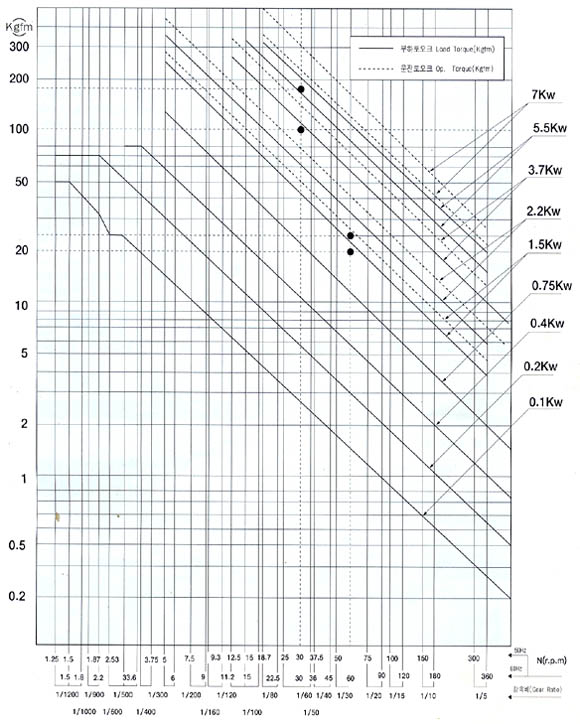

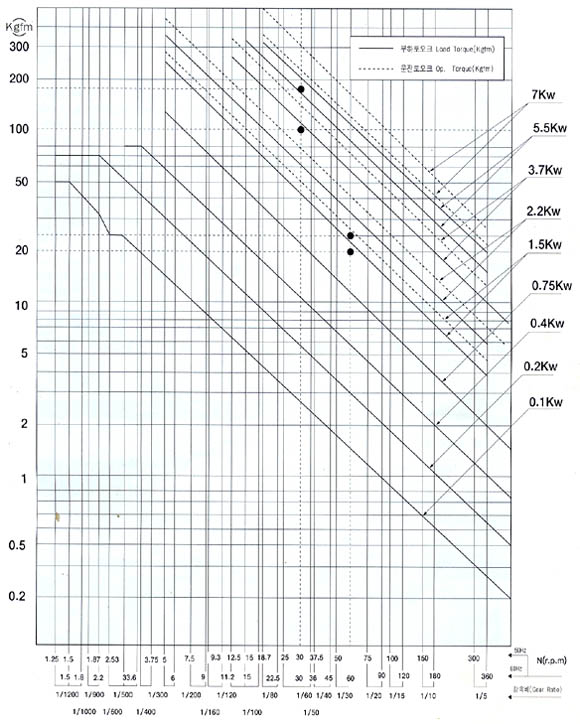

출력의 선정

① 필요한 출력축 회전수 N (RPM)에 따라 감속비를 결정하십시오.

② 부하 토오크 T1 (kgf-m)에서 전달토오크 T (kgf-m)를 산출하십시오.

T = T1 × Sf

Sf (써비스 훽타 ) : 출력축에 작용하는 부하의 성질과 운전시간에 의하여 표1에 표시하였습니다.

③ 산출된 전달토오크 T (kgf-m) 및 부하 토오크 T1 (kgf-m) 과 회전수 N(RPM)에 의하여

그림 1의 출력선정도에 의하여 가가의 모타용량을 구하고 가능한 높은 쪽으로 선정하여 주십시요.

(예)

출력수 회전수 : N = 60RPM (60HZ)

부하토오크 : T1 = 20 kgf-m

피동기 : 콘베어 (균일하중)

운전시간 : 12시간 /일

a. 감속비 ι = 60/1800 = 1/30

b. 전달 토오크 T : 표2 및 표1에 의하여 Sf = 1.25

T = T1 × Sf = 20×1.25 = 25 (kgf-m)

c. 모타출력

부하 토오크 T1 에 의거 N = 60 과 T1 = 20 의 교차점을 구하시오

교차점은 0.75 KW의 1.5KW의 사이

U : 균일하중(Uniform Load)

M : 中 정도 충격 (Medium Impact)

H : 中 정도 충격 (Heavy Impact)

|

Operation Hr./Load

|

U

|

M |

H |

3시간 이하/ 일

(Less 3 Hr/Day) |

1 |

1 |

1.5 |

3~10시간 / 일

(3~10Hr/Day) |

1 |

1.25 |

1.75 |

10시간 이상 / 일

(More than 10 Hr/day) |

1.25 |

1.5 |

2 |

|

|

표2. 피동기계 부하 분류표 (Driven Machine)

피동기계명(Driven Machine) |

부하(Load) |

송풍기 Air Blower

주조 및 증류장치 Distillation

차량 Car

클라리 화이어 Clarifier

선별기 Sorter

요업기계(中 부하) Ceramic Machine (M.Load)

요업기계(重 부하) Ceramic Machine (H.Load)

압축기 Compressor

콘베아 (균일부하) Conveyor (Uniform)

콘베아 (불균일부하) Conveyo (Non- Uniform)

크레인 Crane

크랏샤 Crusher

준설용선박 (中 부하) Drainage (M.Load)

준설용선박 (重 부하) Drainage (H.Load)

엘리베이타 Elevator

압출기 Extruder

휀 Fan

공급기 Supplier

공급기(왕복동식)Supplier(Commuting)

식품기계 Food Machine

헴머빌 Hammer Mill

호이스트 Hoist

공작기계 (주기동) Milling Machine (main)

공작기계 (보조기동) Milling Machine (Sub)

금속가공기계 steel process.Machine

회전밀 Turning mill

턴푸라 Turning Barrels

믹서 Mixer

유압정제기계 Oil Pressure Cleaner

제지기계 Paper Machine

제재기계 Wood Cutter

펌프 Pump

고무기계 (中 부하) Rubber Machine (M.Load)

고무기계 (重 부하) Rubber Machine (H.Load)

수처리기계 (輕 부하) Water Cleaner (L.Load)

수처리기계 (重 부하) Water Cleaner (H.Load)

스크린 (유체) Screen (Oil Based)

제당기계 Sugar Machine

섬유기계 Textile Machine

제철기계 (열간) Iron Works (Heat Treat)

제철기계 (냉간) Iron Works (Cold Treat)

|

U

U

M

U

M

M

H

M

U

M

U

H

M

H

U

U

U

M

H

M

H

M

M

U

H

M

H

M

M

M

H

M

M

H

U

M

U

M

M

H

U

|

그림1 출력선정도

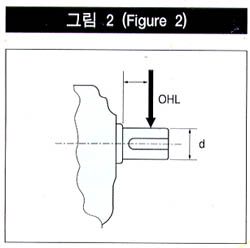

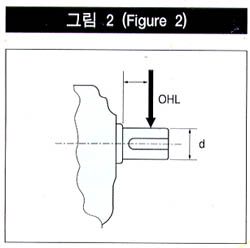

O.H.L(Overhang Load)의 확인

O.H.L은 출력축에 작용하는 굽힘하중의 위치를 표시하고 있습니다. 상대기계와 체인, 기어, 벨트 등으로

연결

한 경우에 발생하며, 카프링에 의한 직결의 경우에는 발생치 않습니다.

O.H.L(kgf) = T1 / R × Sf × Ef × Lf × 1000

T1(kg-m) : 사용 토오크

R(mm) : 스프로켓, 기어, 풀리 등의 피치원 반경

Ef : 연결방법에 따른 Ef 값 (표3에서 구함)

Lf : 작용거리에 따른 Lf 값 (표4에서 구함)

산출한 O.H.L은 사용 기어드 모터의 허용 O.H.L의 이하에서 R 및 Lf을 결정하여 주십시오.

허용 O.H.L은 규격별로 표시되어 있습니다.

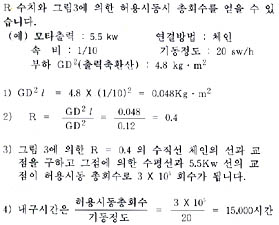

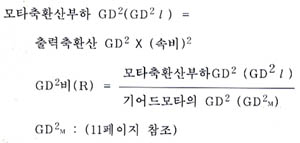

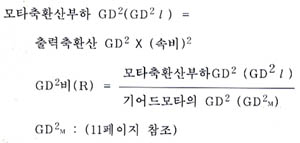

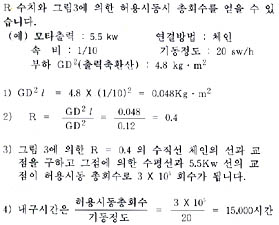

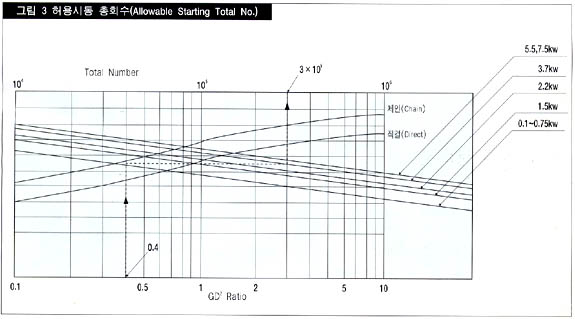

플라이 휠 효과

부하의 관성(GD2 )이 크거나 단속운전을 할 때 시동시 (또는 브레이크에 의한 제동시)에 간헐적으로

커다란

토오크가 발생할 경우에 고장의 원인이 될 수가 있으므로 그림3에 의한 부하의 관성과 허용시동 회수를 확인하여 주십시오.

|

표3 연결방법

단열체인 (Single Row

Chain)

|

1.00 |

타이밍 벨트(Timing Belt)

|

1.00 |

복열체인 (Double Row Chain)

|

1.25 |

기어 (Gear)

|

1.25 |

벨트 (Belt)

|

1.50 |

평벨트 (Plain Belt)

|

2.50 |

|

|

표4 작용위치

L |

Lf |

0.25d |

0.85 |

0.50d |

0.90 |

0.75d |

0.95 |

1.00d |

1.00 |

1.25d |

1.25 |

1.25d |

1.50 |

|

|

|

|

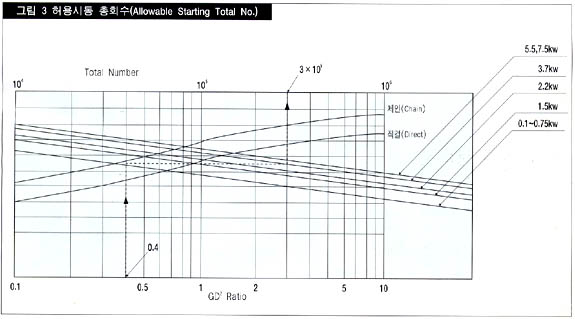

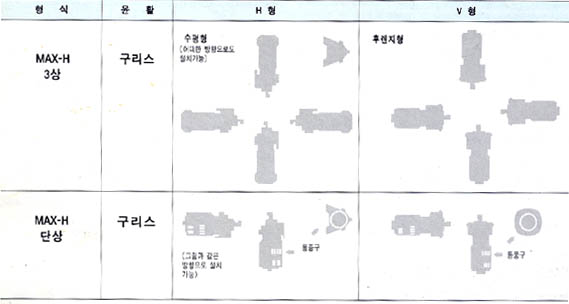

기어드모타 형식별 설치방향

|

|

기어드 모타 규격별 구리스 및 오일 주입량 (Grease

or Oil Charging Quantity)

| Kw |

Lubricant |

1/5 |

1/10 |

1/15 |

1/20 |

1/30 |

1/40 |

1/45 |

1/50 |

1/60 |

1/80 |

1/100 |

1/120 |

1/160 |

1/200 |

| 0.1 |

Grease |

0.1 |

- |

0.1 |

0.42 |

| 0.2 |

0.1 |

0.42 |

- |

0.42 |

0.7 |

| 0.4 |

0.1 |

0.3 |

0.7 |

1.5 |

| 0.75 |

OIL |

0.45 |

0.55 |

1.0 |

| 1.5 |

0.9 |

1.0 |

1.4 |

2.0 |

| 2.2 |

1.0 |

1.4 |

1.9 |

2.5 |

| 3.7 |

1.9 |

2.3 |

3.8 |

| 5.5 |

2.3 |

3.6 |

4.5 |

| 7.5 |

2.3 |

3.6 |

4.3 |

7.0 |

- 공장 출하시에 0.2 ~ 0.4 Kw의 전기종에 구리스를 0.75 ~ 7.5 Kw 전기종에는 오일을

충전하여 출하하고 있습니다.

- 구리스의 교환시기는 2,000 시간마다 교환하여 주십시오.

- 오일의 교환시기는 500 시간 가동후 1회 교환 후 매 2,000시간 마다 교환하여 주십시오.

- 구리스 및 오일 교환시 양은 상기표를 참조 하십시오.

|

|

기어드모타의 GD2M (모타축

환산)

| Kw |

4P |

| 일반형 |

브레이크 부착 |

| 0.4 |

0.0056 |

0.0069 |

| 0.75 |

0.0099 |

0.0112 |

| 1.5 |

0.0271 |

0.0321 |

| 2.2 |

0.0301 |

0.0351 |

| 3.7 |

0.0456 |

0.0967 |

| 5.5 |

0.0633 |

0.114 |

| 7.5 |

0.106 |

0.167 |

|

|

MAX-GM 소음치

GEARDE RATIO |

1/120 |

1/90 |

1/60 |

1/45 |

1/30 |

1/20 |

1/15 |

1/10 |

1/5 |

RPM |

15 |

20 |

30 |

40 |

50 |

90 |

120 |

180 |

360 |

(KW)

출력

OUT

PUT |

0.4 |

52 |

53 |

53 |

53 |

52 |

52 |

52 |

53 |

53 |

0.75 |

57 |

57 |

57 |

58 |

57 |

58 |

58 |

58 |

59 |

1.5 |

61 |

61 |

61 |

60 |

61 |

60 |

61 |

62 |

62 |

2.2 |

61 |

63 |

63 |

64 |

62 |

63 |

63 |

63 |

64 |

3.7 |

68 |

69 |

69 |

69 |

68 |

67 |

68 |

68 |

68 |

5.5 |

69 |

70 |

70 |

69 |

69 |

69 |

69 |

69 |

69 |

7.5 |

|

74 |

74 |

73 |

74 |

75 |

75 |

74 |

75 |

|

|

삼상유도 전동기참고 특징 DATA |

| 출력

Kw(HP) |

극수 |

정격전류 |

기동전류 |

효율

% |

역율

% |

전부하

(Kg-m) |

Slip

% |

R.P.M |

| 220V |

380V |

220V |

380V |

0.4

(½) |

2

4

6 |

2.4

2.6

3.0 |

1.4

1.5

1.7 |

17.4

16.4

19 |

10

9.5

11 |

62.0

63.5

62.0 |

72

63

55 |

. |

8.5

9.0

10 |

3294

1638

1080 |

0.75

(1) |

2

4

6 |

3.6

3.8

4.4 |

2.1

2.2

2.5 |

28

25

29 |

16

15

17 |

68.0

69.5

63.0 |

77

70

63 |

0.42

0.65 |

7.5

8.0

8.5 |

3330

1656

1098 |

1.5

(1½) |

2

4

6 |

4.4

4.6

5.2 |

2.5

2.6

3 |

34

30

33 |

20

17

19 |

71.5

72.0

71.5 |

79

73

66 |

. |

7.0

7.5

8.0 |

3348

1665

1104 |

1.5

(2) |

2

4

6 |

6.4

9.2

7.4 |

3.7

5.3

4.3 |

49

60

48 |

28

35

28 |

74.5

78.5

74.5 |

81

77

69 |

1.24

1.3 |

7.0

7.0

8.0 |

3348

1674

1104 |

2.2

(3) |

2

4

6 |

8.3

9.2

10.4 |

5.1

5.3

6.0 |

68

60

66 |

39

35

38 |

77.0

78.5

77.0 |

81

77

71 |

1.24

1.91 |

6.5

7.0

7.0 |

3366

1674

1116 |

3.7

(5) |

2

4

6 |

14

14.6

15.8 |

8.1

8.4

9.1 |

109

100

104 |

63

58

60 |

80.0

81.0

80.0 |

82

78

73 |

2.09

3.16 |

6.0

6.5

6.5 |

3384

1683

1122 |

5.5

(7½) |

2

4

6 |

21

21.8

23.6 |

12

12.6

13.6 |

159

150

154 |

92

87

89 |

82.0

82.5

82.0 |

79

77

72 |

3.09

4.65 |

6.0

6.0

6.0 |

3384

1692

1128 |

7.5

(10) |

2

4

6 |

28.2

29.2

31 |

16.3

16.8

17.9 |

209

191

205 |

121

110

118 |

83.0

83.5

83.0 |

80

78

73 |

4.2

6.3 |

6.0

6.0

6.0 |

3384

1692

1128 |

|

|

단상유도 전동기 참고 특성

DATA |

| 형식 |

극수 |

출력

(Kw) |

프레임 |

전압

(V) |

전부하 |

기동 |

Torque

(kg·m) |

Current

(A) |

R.P.M |

Torque

(%) |

Current

(A) |

| EOUP |

4 |

0.1 |

71 |

110 |

0.056 |

2.8/1.4 |

1750 |

260 |

15.0/7.5 |

| 0.2 |

71 |

0.112 |

5.6/2.8 |

1750 |

260 |

23/11.5 |

| 0.25 |

71 |

0.139 |

6.4/3.2 |

1745 |

260 |

29/15 |

| 0.3 |

71 |

0.167 |

7.2/3.6 |

1740 |

260 |

33/17 |

| 0.4 |

90 |

0.222 |

8.7/4.4 |

1750 |

265 |

38/19 |

특 징

a) 무여자 작동형 (스프링 크로스식)으로서 정전시에는 자동적으로 작동하는 안전 브레이크입니다

b) 전원장치가 있어 배선이 용이합니다

c) 간단한 구조로 브레이크 갭 조정도 용이합니다.

|

|

브레이크사양 |

\출력(Kw) 4P

사양\ |

0.1 |

0.2 |

0.4 |

0.75 |

1.5 |

2.2 |

3.7 |

5.5 |

7.5 |

| 브레이크 |

SB-0.2 |

SB-1.0 |

SB-1.0 |

SB-2.0 |

SB-3.0 |

SB-6.0 |

SB-8.0 |

SB-8.0X2 |

SB-15 |

| 토오크(kgf.m) |

0.2 |

1.0 |

1.0 |

2.0 |

3.0 |

3.5 |

8 |

12 |

15 |

| 전원장치 |

HD-10 |

HD-20B |

| 전압 |

AC 220V(DC90V) |

| 전류 75℃(A) |

0.082 |

0.27 |

0.27 |

0.25 |

0.27 |

0.3 |

0.4 |

0.4 |

0.56 |

| 용량 75℃(W) |

7.3 |

24 |

24 |

22 |

24 |

27 |

36 |

36 |

36 |

| 규정 틈새 (mm) |

0.2 |

0.3 |

0.4 |

| 한계 틈새 (mm) |

0.8 |

0.8 |

1.5 |

| 허용별 열발산양

1500 R.P.M 50% ED (kgf.m/min) |

100 |

500 |

500 |

600 |

800 |

800 |

1100 |

1100 |

1100 |

| 총사사양 (kgf.m) |

9 x 105 |

2.2 x 107 |

2.2 x 107 |

3.6 x 107 |

4.5 x 107 |

4.5 x 107 |

6.3 x 107 |

8.4 x 107 |

8.4 x 107 |

E.T (kgf.m)

| 개방시간 (sec) |

동시절환 |

0.3 |

0.225 |

0.205 |

0.298 |

0.150 |

0.135 |

0.230 |

1.20 |

1.20 |

| 교류절환 |

0.17 |

0.130 |

0.075 |

0.120 |

0.054 |

0.050 |

0.070 |

0.50 |

0.45 |

| 직류절환 |

- |

0.023 |

0.012 |

0.013 |

- |

- |

- |

0.075 |

0.065 |

|

|

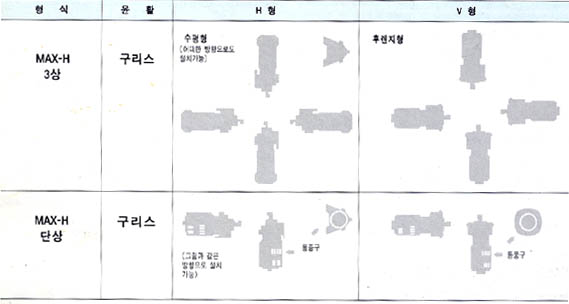

브레이크구조 |

NO. |

명칭 |

1 |

브라켓 쉴드 |

2 |

스터드 볼트 |

3 |

어드져스트 라이너 |

4 |

칼라 |

5 |

육각 너트 |

6 |

코일 |

7 |

자석 |

8 |

소음 브라켓 |

9 |

소음 스프링 |

10 |

호브 |

11 |

브레이크스프링 |

12 |

아마츄어 |

13 |

내부 디스크 |

14 |

브라켓 |

|

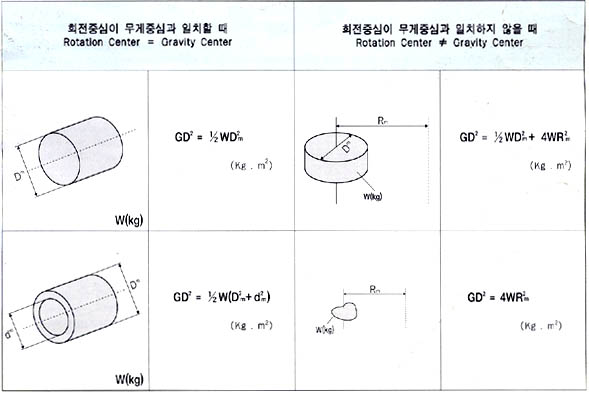

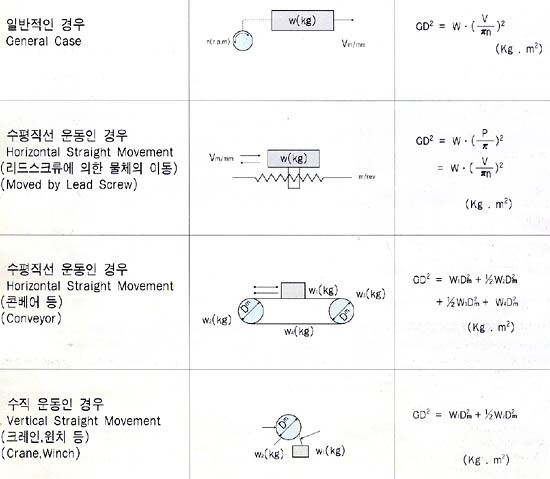

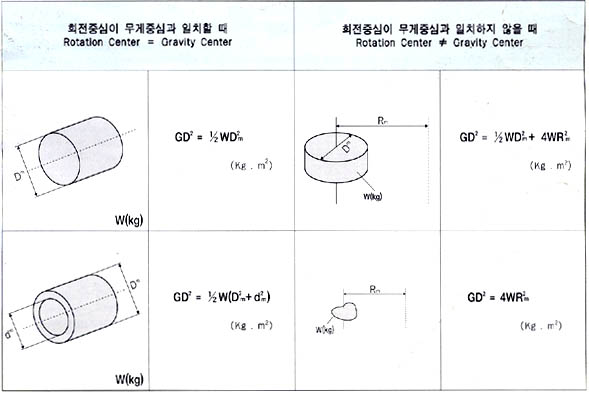

GD2플라이 휠의 효과 계산법

Calculation of Fly Wheel Inertia

관성을 일반적인 관상모멘트 I (Kg .m.sec²)로 나타내고 있습니다만 공업용으로 실제 사용할 경우는

GD2(Kg-m2)을 사용하는 것이 편리하다.

GD²=4gℓ

|

G ------- 중량 Weight(Kg)

D ------- 회전직경 Rotation Diameter

g ------- 중력가속도 Gravity (9.8 m/sec2)

I ------- 관성모멘트 Inertia Momentum |

|

회전체의 GD²

직선운동을 하는 경우의 GD²

|

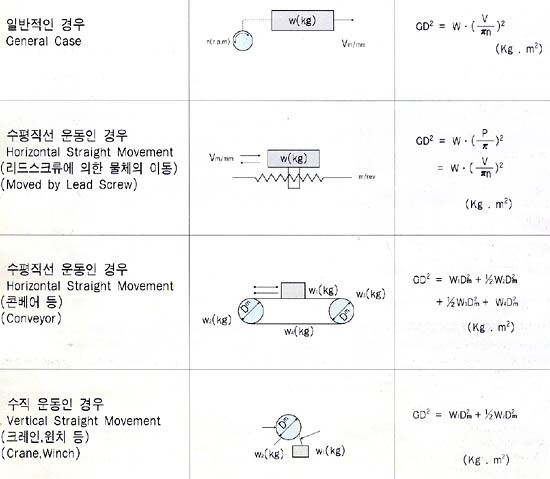

회전비가 있는경우 GD² |

|

부하측의 GD²b를 환산할 경우

Conver sion of load shaft to no shaft

GD² = GD²a + (nb / na)² GD²b

|

|

설치 및 사용상 주의사항

1. 설치전의 점검

감속기는 당공장에서 철저한 검사 및 점검한 후 납품하지만, 수송 도중 진동이나 그의 악영향을 받는 경우가

있으므로 설치 전에 반드시 다음 사항을 점검하십시오,

① 누유되는 곳은 없는가 ② 파손된 부분은 없는가 ③ 명판은 주문 사항과 일치하는가

2. 상대기계와 연결 방식

1) 직결방식

입출력축 모두 직결방식을 사용하는 것이 가장 좋으며 커플링은 가급적 가요성 커플링을 사용하시기 바랍니다.

2) 기어, 체인 스프로켓 사용시

-입출력축에 체인, 스프로켓, 풀리 등을 취부하는 경우 아래의 공식에 의해서 스프로켓 및 기어의 직경을

선정해 주십시오

체인스프로켓 기어의 피치원 직경≥3× 입출력축의 직경

-입출력축의 선단에 하중이 작용하면 축에 무리한 힘이 걸려서 축이 파괴하거나 베어링이 손상될 우려가 있으므로

완전히 안쪽(카바쪽)으로 조립한 후 사용하십시오.

3. 윤활유의 선정 및 보존

1) 주유 및 유량

윤활유는 반드시 추천 윤활유를 사용하고 유량은 완전 정지상태에서 유면계의 중심까지 오게 하십시오. 윤활유가

너무많거나 적으면 기어와 베어링에 약영향을 미칠 우려가 있습니다.

2) 윤활유의 교환

처음 가동시에는 기어의 초기 마모분이 기름에 떨어지므로 운전개시 후 500사건 정도 사용후 새로운 윤활유로

교환하여 윤활유 교환시 내부를 깨끗하게 세척하여 마모분을 제거하십시오.

|

|

추천윤활유

| Type, Maker |

호남정유

CALTEX |

유공

GULF |

극동

SHELL |

MOBIL

KOREA |

| ISO VG 68 |

Meropa Lubricant

68 |

EP Lubricant HD

68 |

Omala

68 |

Mobil gear

626 |

| ISO VG 100 |

Meropa Lubricant

100 |

EP Lubricant HD

100 |

Omala

100 |

Mobil gear

627 |

| ISO VG 150 |

Meropa Lubricant

150 |

EP Lubricant HD

150 |

Omala

150 |

Mobil gear

629 |

| ISO VG 220 |

Meropa Lubricant

220 |

EP Lubricant HD

220 |

Omala

220 |

Mobil gear

630 |

| ISO VG 320 |

Meropa Lubricant

320 |

EP Lubricant HD

320 |

Omala

320 |

Mobil gear

632 |

| ISO VG 460 |

Meropa Lubricant

460 |

EP Lubricant HD

460 |

Omala

460 |

Mobil gear

634 |

| ISO VG 680 |

Meropa Lubricant

680 |

EP Lubricant HD

680 |

Omala

680 |

Mobil gear

636 |

| 구리스 |

NLGI 0 |

Multifax EP 0 |

Crown EP 0 |

Alvania EP 0 |

Mobilplex EP 0 |

| NLGI 1 |

Multifax EP 1 |

Crown EP 1 |

Alvania EP 1 |

Mobilplex EP 1 |

| NLGI 2 |

Multifax EP 2 |

Crown EP 2 |

Alvania EP 2 |

Mobilplex EP 2 |

사용윤활유

| 제품종류 |

하중상태 |

주위온도 |

사용윤활유 |

유성감속기

기어드 모터 |

정하중 |

below 10℃ |

ISO VG 150 |

| above 10℃ |

ISO VG 220 |

| 웜 |

보통하중 |

below 10℃ |

ISO VG 220 |

| above 10℃ |

ISO VG 320 |

| 중하중 |

below 10℃ |

ISO VG 320 |

| above 10℃ |

ISO VG 460 |

| * |

매우 격심한 부하조건의 표준형

감속기에는 한단계 높은 점도의 윤활유를 사용하는 것이 좋습니다. |

| * |

구리스 전용 기어드모터에는

NLGI 0를 사용하십시오. |

| * |

주위온도가 40℃ 이상되는

경우에는 당사에 문의하여 주십시오. |

| * |

사용온도가 높은 경우에는

한단계 높은 점도유를 선택하십시오. |

|

HOME > 제품소개 > 모터

HOME > 제품소개 > 모터