|

|

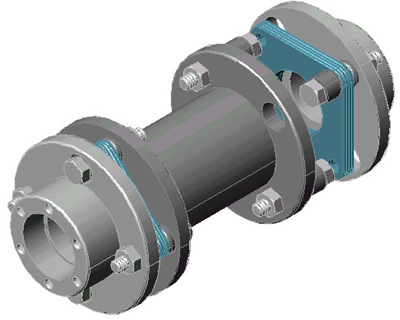

1. 디스크 카플링은 특수카프링의 필수조건인

하이토오크(hitorque이며

고속용이므로 NC장치가부착된

공작기계, 인덱싱(indexing) 장치, 인쇄기등

에는 정확한축의 회전위상제어가 필요 하지만디스크

카플링은 백래시(backlach)가 없고 비틀림강성이

크므로 이와 같은 기계에는 최적입니다.

2. 서로 닿거나 마찰 진동부분이 없으므로 윤활유가필요없습니다.

따라서 소음,

진동 마모가 없고 에너지 손실도낮으며

청결하여 기름이 묻지 않습니다. |

|

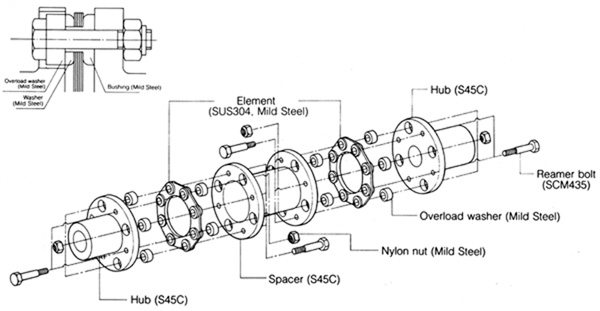

3.디스크카플링 구조의 핵심은 element에 있습니다. 형상은

4, 6, 8,10 각형의 종류가 있으며 특별히

제작된 SUS-304 스프링판을

적층한 것입니다.

4. 디스크카플링은 정확한 setting 으로 초기 환경이 변하지

않으면 수명은 반영구적입니다.

정비는

운전 정지중에 element 또는 Bolt, Nut 상태를 육안 검사만으로 끝냅니다.

돌발사고

등으로 큰 부하가 걸려 만일 element가 파손된다고 해도 볼트가 washer에

끼워져서

회전이 전달되므로 안전합니다.

5. misalignment의 허용범위가 넓으므로 여러가지 system에

유연하게 적응합니다.

또한

특수설계에 의한 커다란 misalignment에도 대응할 수가 있습니다.

misalignment가

흡수될 경우 shaft에 반력이 발생하지만 다른 카플링에 비해 반력을

보다

적게 억제시킬 수 있습니다.

6. 디스크 카플링의 부하능력은 특수한 경우를 제외하고는 극히 낮은 level에서

보존됩니다.

따라서

허용 misalignment 내에 있으면 수명은 반영구적입니다.

부품수가

적고 소형이므로 빠르고 확실하게 설치, 분해가 가능합니다.

또한

조립 재현성이 좋으므로 고속회전기계에 매우 적합합니다. |

|

| |

| |

규격선정방법(Selection Method of Size) |

| |

1. 사용 설비의 토오크를 구합니다.

Ta = 974 x  x SF또는 Ta = 716 x x SF또는 Ta = 716 x  x SF x SF

Ta

= 사용 토오크 (kgf.m)

KW

= 전달 부하

HP

= 전달 마력

N

= 회전수 (r.p.m)

SF=

안전계수(Service factor)

2. 산출된 Torque를 카다로그에 있는 각 Size의 Basic Torque와

비교 하여 크거나 같은

수치를

찾아 1차 규격을 선정 합니다.

3. 하지만 Torque만 허용 범위 안에 해당 된다고 그 규격을 선정 하면 경우에 따라서는

Shaft

Bore를 가공 하려면 가공 여유가 부족할 경우가 있습니다.

따라서

사용 기계의 Shaft 크기와 카플링의 최대 내경(Max. Bore)을 비교 검토

한 다음

최종

규격을 선정 합니다.

4. 즉, 카다로그에 있는 허용 Torque와 최대축경(Max. Bore)이 동시에 만족

되어야 합니다.

|

5. 안전계수표 |

Driving

machines |

Load |

Examples

of driven machines |

Electric

motor

or turbine |

Hydraulic

power |

Reciprocating

motion |

1 |

1.25 |

1.5 |

smooth |

Pumps,

Blowers, Generators, and Exciters |

1.5 |

.8 |

2 |

Light

shock |

Compressors,

Mixers, Grinders, Machine Tools,

Wood Working machines, and Texile

Machine |

2 |

2.3 |

2.5 |

Medium

shock |

Ball

and Rol MIls, Reciprocating

Compressors, Elevators, Paper

Machines, Punch Presses. |

2.5 |

2.8 |

3 |

Heavy

shock |

Steel

& Iron Manufacturing Macines,

Mining Machines,

Roll Mills, and Rubber Mixer |

3 |

3.5 |

4 |

ExtremelyHeavy

shock |

Ore

Crushers, Vibrating conveyors, and

cutters |

|

|

|

| |

디스크 커플링의 분류 및 용도, 호칭 (Type of Flexible Elements) |

|

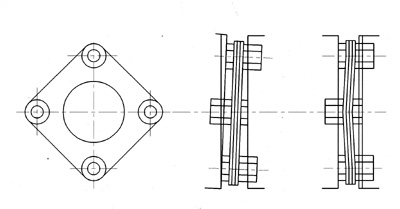

isk

Pack 모양에 따른 분류 및 호칭 |

|

|

|

|

|

|

Max.

angullar

misalignment |

1˚ |

0.7˚ |

0.5˚ |

0.35˚ |

Allowable

Torque(kg.m) |

3.4

~ 650 |

58

~ 13070 |

392

~ 18150 |

1379

~ 26130 |

single

type |

A3 |

E3 |

G3 |

S3 |

double

type |

short

space |

AX |

- |

- |

- |

standard

space |

A4 |

E4 |

G4 |

S4 |

custom

space |

AB |

EB |

GB |

SB |

floating

type |

horizontal |

A5 |

E5 |

G5 |

S5 |

vertical |

A7 |

E7 |

G7 |

S7 |

|

|

위 그림의 표는 Disk Pack 모양에 따라 예를

들어 보면

single disk coupling 4-bolt는 A3 type, double disk

coupling 4-bolt는 A4 type

single disk coupling 6-bolt는 E3 type, double disk

coupling 6-bolt는 E4 type

이라고 호칭 한다는 의미 입니다. |

| |

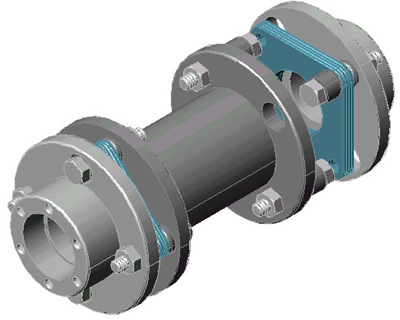

Disk

coupling의 종류 및 용도 |

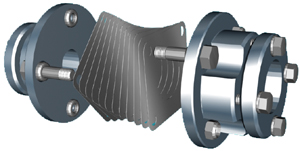

Single Disk Flexible

Coupling ( A3 TYPE )

:큰 연직 하중(Radial Load)을 허용하며, 세개의 Bearing이

지지될 경우에 주로 사용되고

편각과 축 유동오차를 흡수 하는 경우에 적합하며 NC 공작 기계와 같이 Ball

Screw와

Servo Motor를 Backlash 없이 연결 할 경우에 주로 사용됩니다.

Double Disk Flexible

Coupling ( A4, E4, G4, S4 TYPE )

:각각의 축에 2개씩의 Bearing이 지지될 경우에 사용하며, 편심, 편각및

축 유동 오차를

흡수 합니다.

지지되는 Bearing은 Coupling의 Hub에 대해서 적절한 거리내에

있을 필요가 있습니다.

Floating Shaft Disk

Flexible Coupling ( A5, A7, E5, E7, G5, G7,

S5, S7 TYPE )

:멀리 떨어진 장소 및 편심 편각이 심하게 요구되는 곳에 사용 되며, Horizontal

( A5, E5, G5, S5 TYPE ) 방향 설치및 Vertical( A7,

E7, G7, S7 type ) 방향 으로도

설치가 가능 하며 주로 Cooling Tower에 많이 사용 되고 있습니다 |

|

|

|

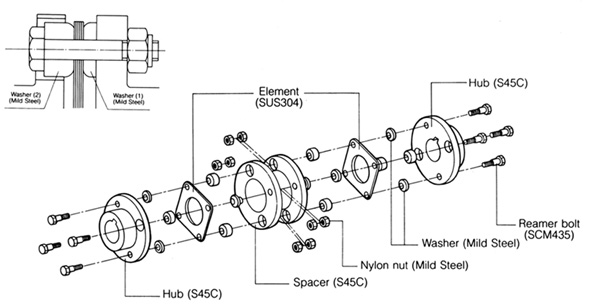

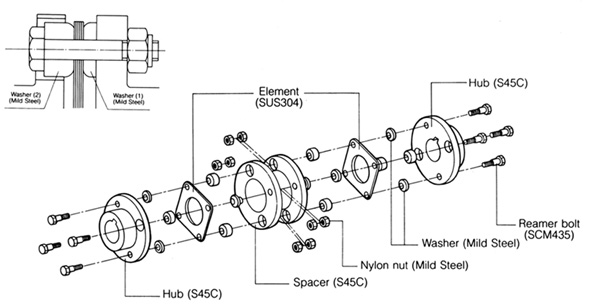

분해도 (Design features of Disk coupling) |

A-type

(4 Bolt용) 분해도 |

|

| |

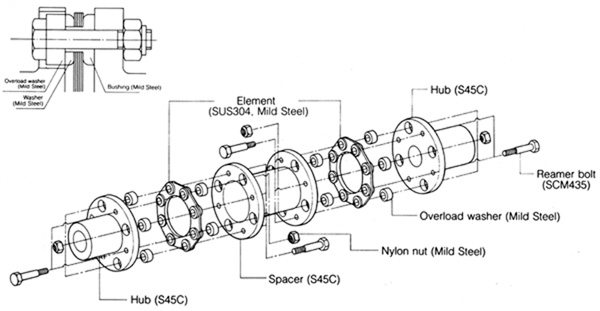

E-type

(6 Bolt용), G-type (8 Bolt용), S-type (10 Bolt용)

분해도 |

|

|

|

|

조립 및 사용방법(How to use Disk couplings) |

최초

조립시 중심 내기에 주의를 기울이는 것은 Coupling에 최대의 능력을 발휘 하게

하고 편심을 보정 하며 장기 수명을 유지 하게 합니다. |

|

1. 축및 내경을 조사 하여 이물질이 없는지 확인 하십시오.

2. 軸端 間의 거리는 칫수표 G 값을 참조 하시고 허용 범위는

0.25 mm 이내에 맞추십시오.

3.편각을 확인 합니다.

1) 다이알 게이지를 한쪽 Hub에 고정 하고 그 Hub를 회전 시켜 다이알

게이지의 눈금

으로 "0" 포인트를 결정 합니다.

2) 다이알 게이지 측 Coupling을 360°회전 시켜 다이알 게이지

눈금이 최소 흔들림이

될때 까지 조정 합니다.

(참고로 편각이 0.1˚ 존재 하는 경우의 측면 흔들림은 아래 표와 같습니다)

3) 편심, 편각이 허용 범위 내에 있는지 재확인 합니다. |

| |

Size No, |

00 |

01 |

02 |

03 |

04 |

05 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

55 |

60 |

65 |

게이지

눈금

(TIR mm) |

A-type |

- |

- |

- |

- |

- |

0.12 |

0.15 |

0.16 |

0.20 |

0.22 |

0.25 |

0.29 |

0.34 |

0.37 |

0.43 |

0.48 |

- |

- |

E-type |

0.21 |

0.24 |

0.28 |

0.32 |

0.37 |

0.48 |

0.48 |

0.53 |

0.60 |

0.65 |

0.71 |

0.77 |

0.81 |

0.88 |

0.96 |

1.02 |

1.09 |

1.13 |

G-type |

- |

0.37 |

- |

0.43 |

- |

0.48 |

0.48 |

0.53 |

0.60 |

0.65 |

0.71 |

0.77 |

0.81 |

0.88 |

0.96 |

1.02 |

1.09 |

1.13 |

|

| |

|

4. 편심을 확인 합니다.

1) 축의 편심은 다이알 게이지를 구동축 Hub에 고정 하고 구동측 축을 회전

시키면서

피동측 Hub의 외경 다이알 게이지 수치를 체크 합니다.

(Flange 1000mm당 2mm의 편심은 편각 0.1°임)

2) 설비를 움직 이거나 받침판을 이용 하여 최대 허용치 이내로 조정 하고

재 확인

하십시오.

5. 오랜 수명을 유지 하기 위해서는 설치 시운전후 2시간 이내에

편심, 편각을 재 확인

하십시오.

재조립시 Nylon Nut는 규정된 torque 값으로 확실 하게 체결 하고

nylon Nut의 사용은

10회 정도가 적당 합니다. |

|

|

|

표준 FLoating shaft의 회전 한계 |

아래의

표는 카플링 중간에 장축(長軸)을 연결할때 사용 RPM에 따라 장축의 길이(mm)를

규제

하는 표입니다.

아래의 길이를 벗어나게 사용 하려면 당사에 문의 바랍니다. |

|

A-type

(4-Bolt용) |

Size

No. |

Maximum

shaft

Diameter(mm) |

사용회전수에

대한 최대 축단간 거리

Maximum Span DMax (mm) for Various

Speed(rpm) |

Standard

Hub |

Z(K)

Hub |

1800 |

1500 |

1200 |

1000 |

900 |

750 |

720 |

600 |

500 |

10 |

32 |

40 |

1610 |

1760 |

1970 |

2160 |

2280 |

2500 |

2550 |

2790 |

3060 |

15 |

35 |

40 |

1690 |

1850 |

2070 |

2270 |

2390 |

2620 |

2670 |

2930 |

3210 |

20 |

42 |

48 |

1880 |

2050 |

2300 |

2520 |

2650 |

2910 |

2970 |

3250 |

3560 |

25 |

50 |

60 |

2010 |

2210 |

2470 |

2700 |

2850 |

3120 |

3190 |

3490 |

3830 |

30 |

58 |

70 |

2220 |

2430 |

2720 |

2980 |

3140 |

3440 |

3510 |

3850 |

4210 |

35 |

74 |

85 |

2500 |

2740 |

3060 |

3350 |

3540 |

3870 |

3950 |

4330 |

4750 |

40 |

83 |

95 |

2690 |

2950 |

3300 |

3610 |

3800 |

4180 |

4250 |

4660 |

5120 |

45 |

95 |

110 |

2890 |

3170 |

3540 |

3880 |

4090 |

4490 |

4570 |

5010 |

5500 |

50 |

109 |

120 |

3100 |

3400 |

3800 |

4160 |

4390 |

4820 |

4910 |

5370 |

5900 |

55 |

118 |

130 |

3230 |

3540 |

3960 |

4330 |

4560 |

5010 |

5100 |

5590 |

|

|

| |

E-type

(6-Bolt용) |

사용회전수에

대한 최대 축단간 거리

Maximum distance between shaft ends DMax

(mm) for Various Speed(rpm) |

Size

No. |

Standard

Hub |

1800 |

1500 |

1200 |

1000 |

900 |

750 |

720 |

600 |

500 |

00 |

51 |

2010 |

2210 |

2470 |

2700 |

2850 |

3120 |

3190 |

3490 |

3830 |

01 |

55 |

2220 |

2430 |

2720 |

2980 |

3140 |

3440 |

3510 |

3850 |

4210 |

02 |

67 |

2500 |

2740 |

3060 |

3350 |

3540 |

3870 |

3950 |

4330 |

4750 |

03 |

72 |

2890 |

3170 |

3540 |

3880 |

4090 |

4490 |

4570 |

5010 |

5500 |

04 |

85 |

3100 |

3400 |

3800 |

4160 |

4390 |

4820 |

4910 |

5370 |

5900 |

05 |

111 |

3100 |

3400 |

3800 |

4160 |

4390 |

4820 |

4910 |

5370 |

5900 |

10 |

111 |

3100 |

3400 |

3800 |

4160 |

4390 |

4820 |

4910 |

5370 |

5900 |

15 |

133 |

3230 |

3540 |

3960 |

4330 |

4560 |

5010 |

5100 |

5590 |

|

20 |

152 |

3720 |

4070 |

4560 |

4990 |

5250 |

5770 |

5880 |

|

|

25 |

165 |

3720 |

4070 |

4560 |

4990 |

5250 |

5770 |

5880 |

|

|

|

| |

G-type

(8-Bolt용) |

사용회전수에

대한 최대 축단간 거리

Maximum distance between shaft ends DMax

(mm) for Various Speed(rpm) |

Size

No. |

Standard

Hub |

1800 |

1500 |

1200 |

1000 |

900 |

750 |

720 |

600 |

500 |

01 |

95 |

2890 |

3170 |

3540 |

3880 |

4090 |

4490 |

4570 |

5010 |

5500 |

03 |

108 |

3100 |

3400 |

3800 |

4160 |

4390 |

4820 |

4910 |

5370 |

5900 |

05 |

111 |

3100 |

3400 |

3800 |

4160 |

4390 |

4820 |

4910 |

5370 |

5900 |

10 |

111 |

3100 |

3400 |

3800 |

4160 |

4390 |

4820 |

4910 |

5370 |

5900 |

15 |

133 |

3230 |

3540 |

3960 |

4330 |

4560 |

5010 |

5100 |

5590 |

|

20 |

152 |

3720 |

4070 |

4560 |

4990 |

5250 |

5770 |

5880 |

|

|

25 |

165 |

3680 |

4030 |

4510 |

4940 |

5200 |

5710 |

5810 |

|

|

|

|

| |

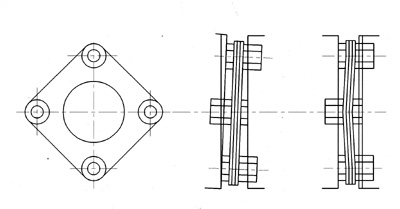

Torque 전달방법 |

|

1. Torque 전달방식은 동일 피치원상에 교대로 구동, 피구동 Bolt를 배치하여

Disk Pack과

연결,

볼트 간의 전달력, 면압력 등에 의해 이루어 집니다.

축오차의

흡수는 어떠한 현상의 경우도 Disk Pack의 탄성 굴곡에 의해 가능하며

그

대표적인 작동 모양은 아래 그림과 같이 되어 집니다. |

|

(편각의

흡수) (축방향 변위의 흡수) |

2. 보다

큰 유연성을 갖게 하는데는 구동 및 피구동의 볼트간 거리를 길게 (Spacer Type)

하는

것과 Disk Pack의 형식을 다각형화(Bolt 갯수가 n개의 경우 n각형, 대개

4, 6, 8, 10

각형

정도가 보통임) 하는 것이 효과적 입니다. |

|

|

HOME > 제품소개 > 동력전달장치

HOME > 제품소개 > 동력전달장치