|

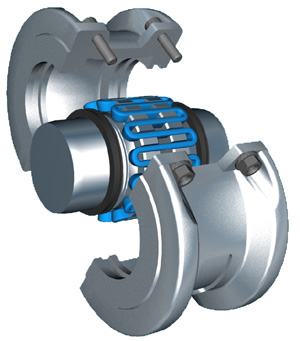

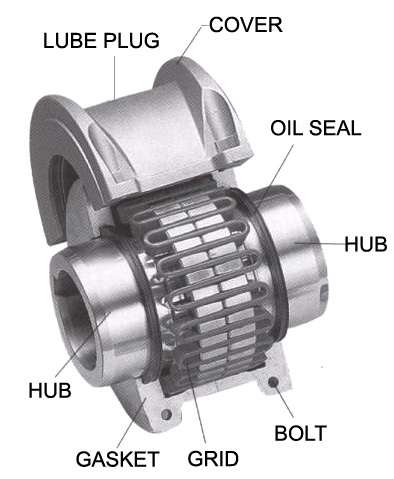

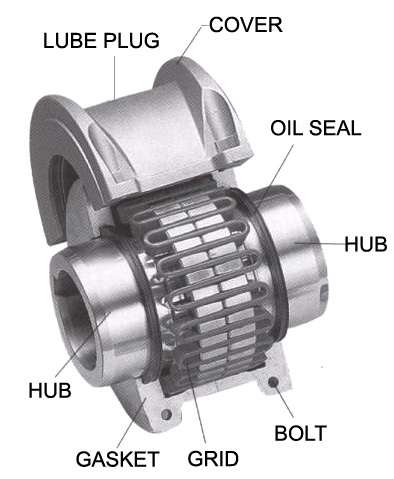

SH-type |

|

|

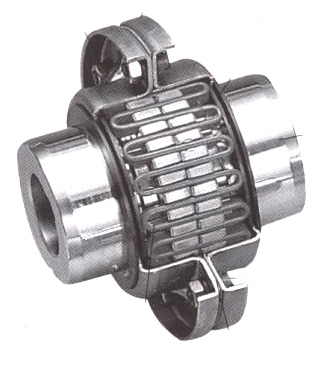

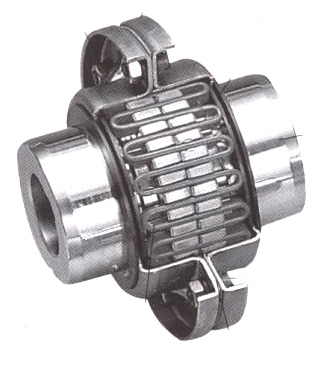

SV-type |

|

| |

|

규격선정방법(Selection Method of Size) |

1. 사용 설비의 토오크를 구합니다.

Ta = 974 x  x SF또는 Ta = 716 x x SF또는 Ta = 716 x  x SF x SF

Ta = 사용 토오크 (kgf.m)

KW = 전달 부하

HP = 전달 마력

N 회전수 (r.p.m)

안전계수(Service factor)

2. 산출된 Torque를 카다로그에 있는 각 Size의 Basic Torque와

비교 하여 크거나 같은

수치를 찾아 1차 규격을 선정 합니다.

3. 하지만 Torque만 허용 범위 안에 해당 된다고 그 규격을 선정 하면 경우에

따라서는

Shaft Bore를 가공 하려면 가공 여유가 부족할 경우가 있습니다.

따라서 사용 기계의 Shaft 크기와 카플링의 최대 내경(Max. Bore)을 비교 검토

한 다음

최종 규격을 선정 합니다.

4. 즉, 카다로그에 있는 허용 Torque와 최대축경(Max. Bore)이 동시에

만족 되어야 합니다.

5. 안전계수표 |

| |

Driving machines |

Load |

Examples of driven machines |

Electric motor

or turbine |

Hydraulic

power |

Reciprocating

motion |

1ㄷ |

1.25 |

1.5 |

smooth |

Pumps, Blowers, Generators,

Exciters |

1.5 |

1.8 |

2 |

Light shock |

Compressors, Mixers, Grinders,

Machine Tools, Wood Working and Texile Machine |

2 |

2.3 |

2.5 |

Medium shock |

Ball and Rol MIls, Reciprocating

Compressors, Elevators, Paper Machines,

Punch Presses. |

2.5 |

2.8 |

3 |

Heavy shock |

Steel & Iron Manufacturing

Macines, Mining Machines,

Roll Mills, and Rubber Mixer |

3 |

3.5 |

4 |

ExtremelyHeavy

shock |

Ore

Crushers, Vibrating conveyors, and cutters |

|

|

|

윤활과 취급 |

1. Grease 윤활

그리드를 Hub와 조립 한후 Grease를 발라주고 Cover를 조립 한후 Grease

주입구를 통해 Grease를 주입 합니다.

2. 보충 및 교환

Grease 보충은 매3개월, 또는 240~250시간 가동 후 보충하고 매 3개월,

혹은 4,000시간 사용 후 Coupling을 완전 분해하여 변질된 것을 새 Grease로

완전 보충 합니다.

3. Grease의 선택

Grease의 사용온도는 -17 ~ 70˚C이고 사용 rpm과 주위 여건에 알맞게

선택해야 합니다.

4. 추천 Grease |

|

Makers |

Gear

Oil |

GULF |

Gulf

crown Grease #2 |

SHELL |

Albania

Grease #2 |

TEXACO |

Marfak

Heavy Duty #2 |

MOBIL |

Mpbilux

#2 |

|

|

|

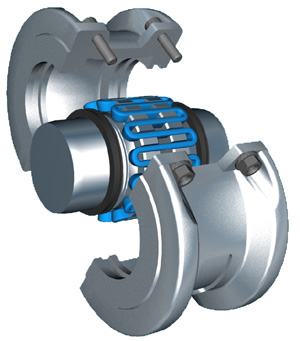

그리드 작동 상태 (Torsional flexisility) |

1. 경하중 작용시 Grid 상태

Grid가 Hub Tooth 외각에서 힘을 받아 직선인 상태로 작동됨으로 부하가 발생하면

Tooth의 곡면과 Grid의 탄력작용으로 Vibration 과 Shocking을

없애 줍니다. |

|

2. 정상부하에서의 Grid상태

부하가 발생하면 힘의 걸림점이 Hub의 Tooth중간으로 이동되어 Grid가 휘어지는

탄력으로 충격하중을 완화시켜 전동 합니다. |

|

3. 시동시 충격부하에서의 Grid상태

순간적인 과부하로 힘의 걸림점이 Hub의 Tooth 제일 안쪽으로 이동되어 Grid가

비틀리는 탄력의 범위 내에서 극도의 충격을 유연하게 완화시켜 Starting 됩니다. |

|

|

1. 모든 금속부품을 세척유로

닦은 후 Oil Seal에 Grease를 칠하여 끼운 후

Hub를 축에 장착 한다. |

|

2. 간격 게이지를 이용 하여 원주상의

틈새가 같도록 조정 한다. |

|

3. 곧은 자로 원주 90도마다 평행오차를조정하고

다이얼 게이지로 축심오차를

더 정확히 조정하여 명시 한계를넘지않도록 유의한다. |

|

4. Hub의 Tooth홈에 Grease를 칠한후Grid를

같은 방향 으로 하여 끼워 넣는다. |

|

5. Grid 주위에 Grease를 충분히 칠하고 Gasket을

아래쪽 Cover 조립면에

놓은후 Match Mark가 필히 같은 방향 으로 오도록 하여 Cover를

조립 한다. |

|

|

6. 축 장착 오차는

아래 표 범위 이내로 맞춰 주실 것을 권해 드리며, 장착후 사용 오차 역시

되도록 아래표 범위에서 사용 되어 질 것을 권해 드립니다. |

| |

SIZE |

추천

장착 오차 |

장착후

사용 오차 |

Normal

gap

±10% |

평행오차

(Parallel offset)

단위:

mm |

각도오차

(Angular)

단위: ˚ |

평행오차

(Parallel offset)

단위:

mm |

각도오차

(Angular)

단위: ˚ |

20S |

0.15 |

0.06 |

0.30 |

0.24 |

3 |

30S |

0.15 |

0.07 |

0.30 |

0.29 |

3 |

40S |

0.15 |

0.08 |

0.30 |

0.32 |

3 |

50S |

0.20 |

0.10 |

0.40 |

0.39 |

3 |

60S |

0.20 |

0.11 |

0.40 |

0.45 |

3 |

70S |

0.20 |

0.12 |

0.40 |

0.50 |

3 |

80S |

0.20 |

0.15 |

0.40 |

0.61 |

3 |

90S |

0.20 |

0.17 |

0.40 |

0.70 |

3 |

100S |

0.25 |

0.20 |

0.50 |

0.82 |

4.5 |

110S |

0.25 |

0.22 |

0.50 |

0.90 |

4.5 |

120S |

0.28 |

0.25 |

0.56 |

1.01 |

6 |

130S |

0.28 |

0.30 |

0.56 |

1.19 |

6 |

140S |

0.28 |

0.33 |

0.56 |

1.34 |

6 |

150S |

0.30 |

0.39 |

0.60 |

1.56 |

6 |

160S |

0.30 |

0.44 |

0.60 |

1.77 |

6 |

170S |

0.30 |

0.50 |

0.60 |

2.00 |

6 |

180S |

0.38 |

0.56 |

0.76 |

2.26 |

6 |

190S |

0.38 |

0.61 |

0.76 |

2.44 |

6 |

200S |

0.38 |

0.68 |

0.76 |

2.72 |

6 |

|

|

|

특징 (Distinctive) |

|

1. 평행오차

축이 편심 상태일 때 Grid가 Grease를 칠한 홈안에서 작동함으로써 진동이나

충격을 완화시켜 무리함이 없는 동력전달을 합니다.(허용치 2mm~3mm)

2. 각도오차

편각(2° ~3°)상태에서도 곡면으로 파여진 Hub의 홈(Groove)안에서,

Grid가 미끌어지는 윤활

작동과 탄력으로 동력이 손실없이 전달, 작동 됩니다.

3.축 유동오차

동축과 종동축이 상하진동과 좌우 유동 되더라도 Grease를 칠한 Hub의

홈 안에서 Grid가 구부러진 안쪽까지 자유로이 작동 하므로 진동의 전달을

방지하고 동력을 전달합니다.

4. 비틀림에 대한 유연성

기계가 시동시 발생하는 충격, 진동, 과부하 등이 Grid에 작용하게 되면

Grid의 유연성

으로 인해 힘의 작용점이 Thooth 의 곡면안에서 진동되므로 진동과 충격부하를

감소

시켜 줍니다. |

|

5. 사용중 과부하가 발생 하면 Grid가 cutting

되므로 안전핀 역할을 하며 샤프트나 기계의

파손을 방지 합니다.

6. 아래와 같은 경우에 주로 사용 됩니다.

1) 진동.충격의 전달을 방지해야 하는 경우

2) 편심이 발생하는 상태에서 정상적으로 동력을 전달해야 하는 경우

3)편각이 이루어진 상태에서 정상적으로 동력을 전달해야 하는 경우

4) 축유동이 발생하는 연결부위에서 정상적으로 동력을 전달하고자 할 때

5) 주기적인 과부하가 발생되는 장소에서 연관 기계의 손상을 방지해야 하는 경우

6) 정.역회전이 요구 되는 경우

7) 충격부하를 완화시켜 시동하고자 하는 경우 |

|

|

HOME > 제품소개 > 동력전달장치

HOME > 제품소개 > 동력전달장치

x SF또는 Ta = 716 x

x SF또는 Ta = 716 x  x SF

x SF